Plate lamination in carbon steel happens when folds or layers of plates are rolled together into a single plate thickness.

Causes of lamination in steel.

Small hysteresis area resulting in low power loss per cycle low core loss and high permeability.

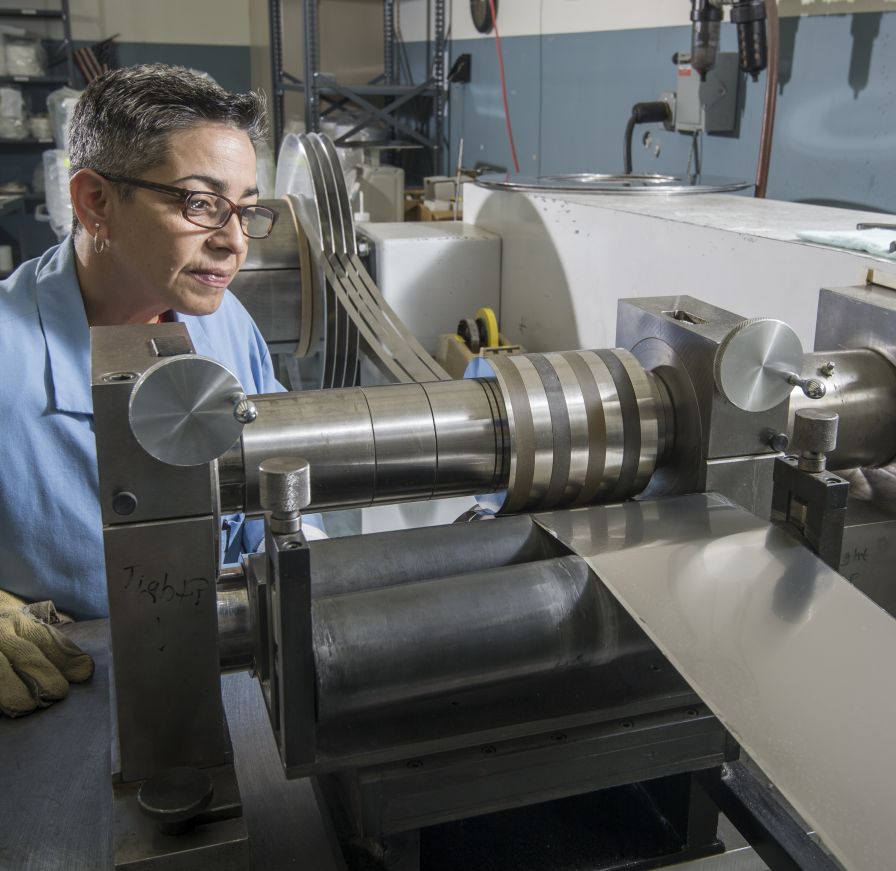

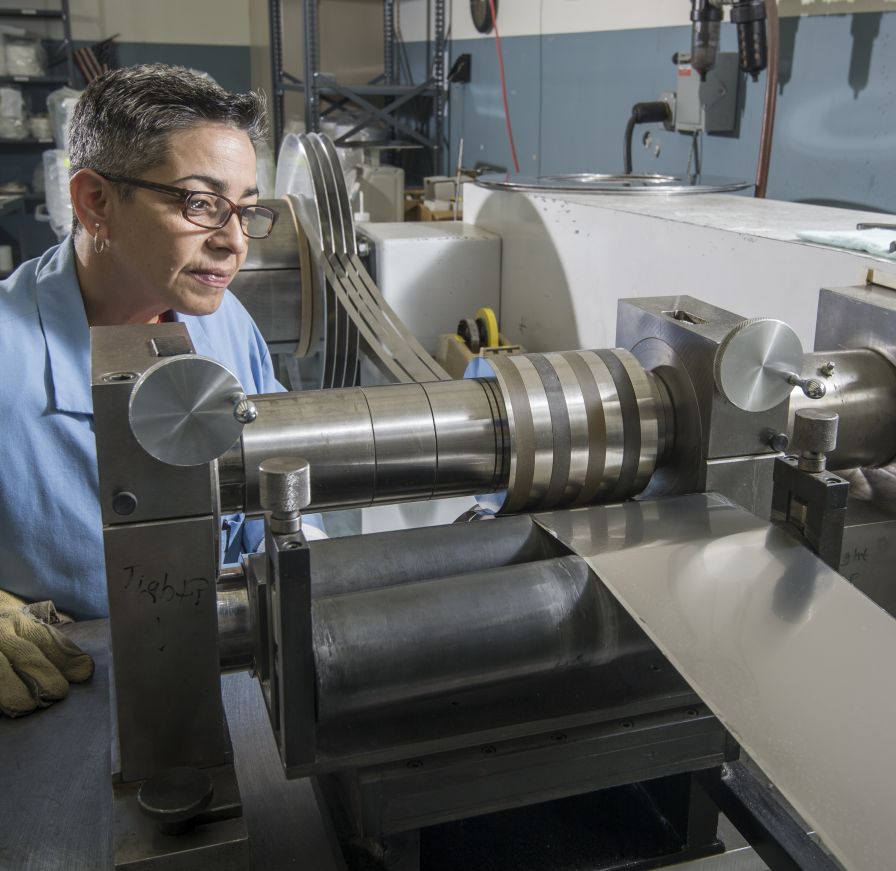

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.

The wrong temperature impurities etc.

Rolled steel bar stock is made by rolling and rerolling steel billets until the desired shape and dimensions are attained.

Lamination in carbon steel plates can occur within the body of a plate or at edges.

Electrical steel is an iron alloy tailored to produce specific magnetic properties.

Can cause a poor weld to be made.

The laminate will stick together but applying and bending force can cause it to delaminate.

These strips are cut to shape to make laminations which are stacked together to form the laminated cores of transformers and the stator and rotor of electric motors.

Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3d printing which can fail from layer separation.

These folds and layers do not bond together and will separate when metal is worked.

Laminations are an imperfection in a steel or alloy resulting from blisters seams foreign material and or scratches on an ingot or billet that are not repaired during the rolling process.

Also surface coatings such as paints and films can delaminate from the coated substrate.