Even with the best chemical treatment program impurities in the cooling tower can only be allowed to accumulate to a certain level before the scaling potential overwhelms the chemical treatment.

Chemicals used in cooling tower water treatment pdf.

We sell to everyone.

Treatment of cooling water will be different depending upon the kind of system in use.

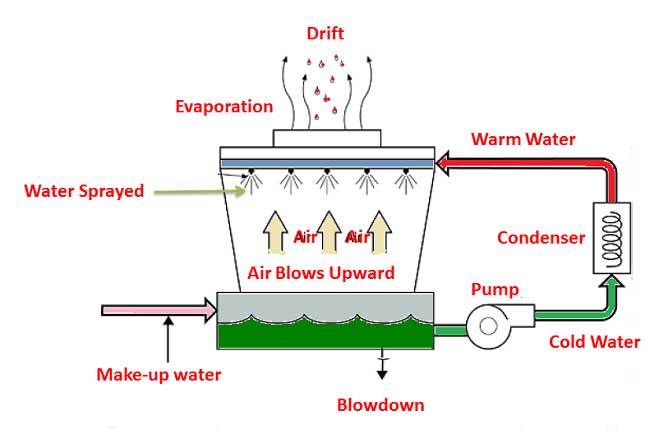

In a counter flow cooling tower water sprays are used to distribute the warm water see figure 8.

Cooling tower chemicals establishes as the most cost effective industrial water treatment program with respect to energy water and chemical usage.

The fan deck supports the motor and fan of the water spray system.

Two most commonly used chemicals in cooling tower water treatment.

These cooling tower water treatment chemicals are used for preventing problems like corrosion scale deposition and microbial growth in cooling towers.

Here are the basic types.

Scaling if untreated for long reduces area available to carry water causes inefficient heat dissipation and blockage of pipelines.

Order online or call 800 768 5810.

You might want to read.

Meanwhile many chemicals used on this water treatment can be so expensive.

If cooling tower water is untreated fouling scaling organic compound and corrosion can form and that reduces plant productivity.

5 water is used around the world in industrial.

Stop corrosion scale build up.

Chemicals used to control microbial populations can be grouped in three general classes based.

Cooling water tower system benefits.

Cooling tower chemicals will help maintain efficiency by preventing corrosion scale deposition and biofilm growth.

Ozone and chlorine dioxide gasses are both highly effective treatments for legionella but are not widely used due to the cost and technical expertise required to properly administer the program and maintain the equipment required to generate the gasses onsite.

Thus that s all the chemicals used in cooling tower water treatment.

For industries using a cooling tower some type of cooling tower water treatment system is necessary to ensure long equipment service life and efficient performance.

In a cross flow cooling tower the hot water basin is used to distribute the warm return water flow uniformly over the tower fill see figure 6.

Cooling tower makeup water.

Differences between acid base and salt.

Treatment chemicals for high medium low capacity cooling towers.

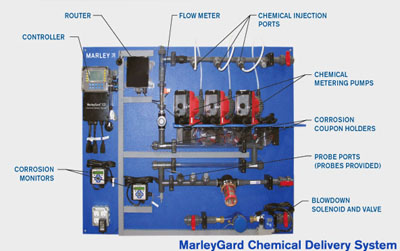

Selecting the proper water treatment program depends on the size and location of your cooling tower.

Universal water chemicals pvt ltd is a leading manufacturer and supplier of an extensive range of cooling tower water treatment chemicals.